Catalyzing Your Adventure

Reaction Composites designs and manufactures precision engineered, meticulously-crafted carbon fiber components using advanced filament winding technology.

Featured Products

American made filament wound carbon fiber parts.

-

Sold out

Sold outUltra Light Stake Out Pole

Regular price From $95.00 USDRegular priceUnit price / per -

2 Foot Gaff

Regular price $95.00 USDRegular priceUnit price / per -

Filament Wound Shade Pole (Pair)

Regular price From $300.00 USDRegular priceUnit price / per -

6 Foot Gaff

Regular price $245.00 USDRegular priceUnit price / per

Our Process

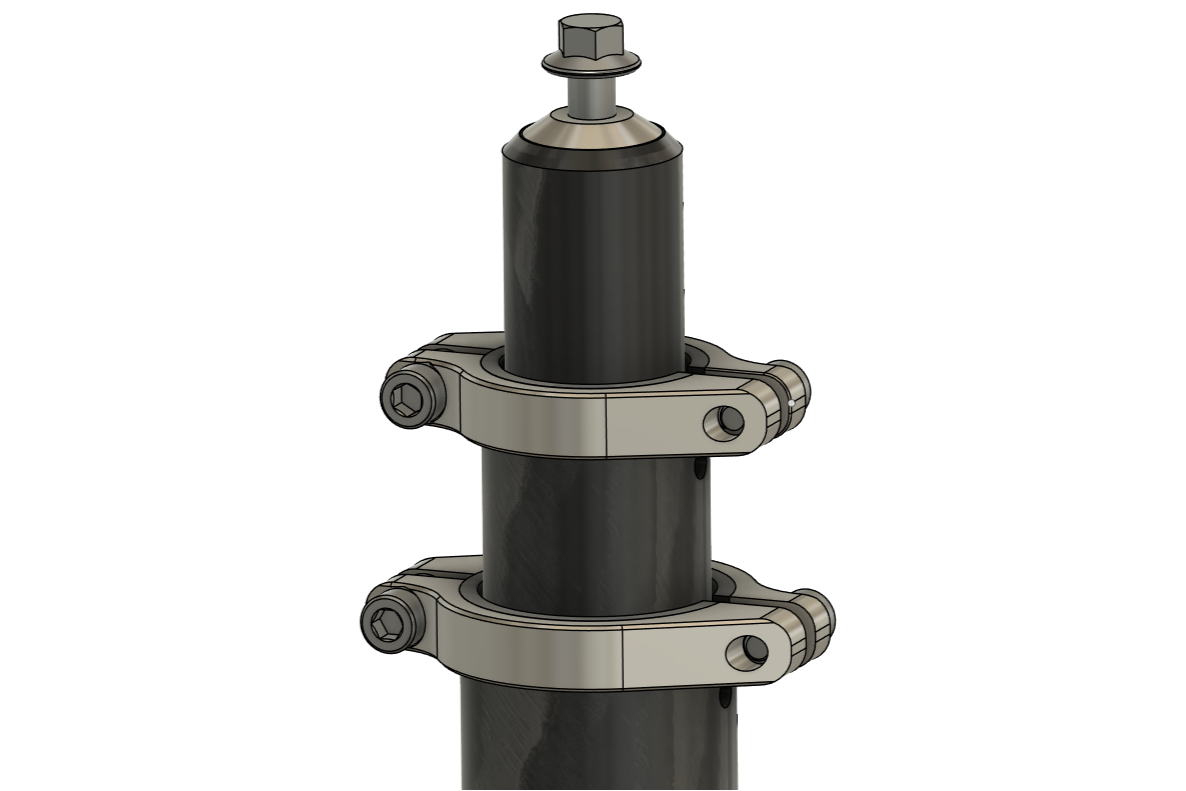

Product Design

Every Reaction Composites product starts with advanced 3D modeling and Finite Element Analysis (FEA) to ensure optimal strength-to-weight ratios. Our engineering process is driven by real-world performance simulations.

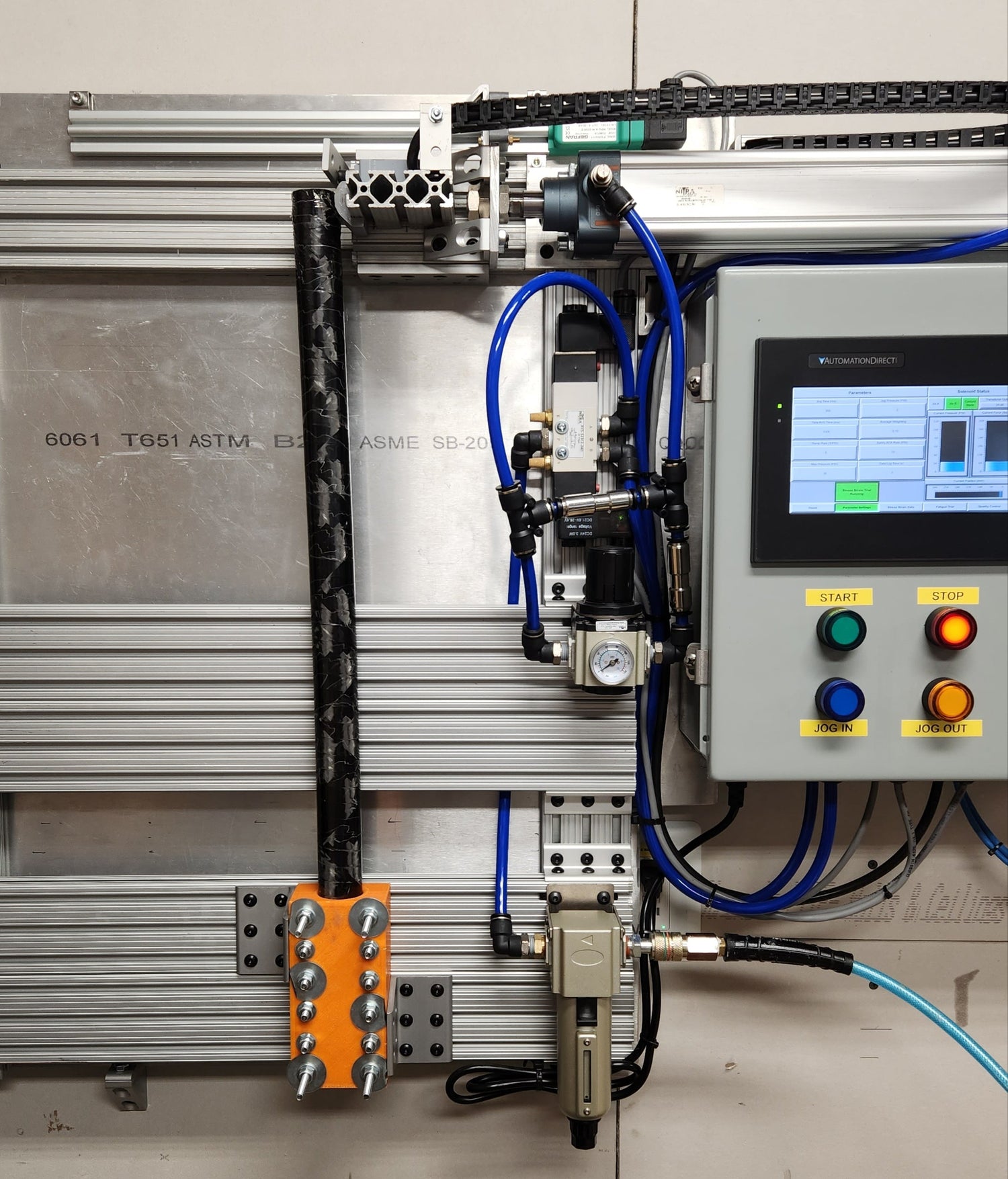

Filament Winding

Our in-house filament winding process combines automation, servo-driven precision, and real-time tension control to create seamless, high-performance carbon fiber components with a unique blend of cost effectiveness and customization. We source all materials domestically for uncompromising quality.

Assembly

Each product is meticulously assembled with aerospace-grade hardware and UV-stable coatings, ensuring durability in the harshest marine environments. Attention to detail at every step guarantees a flawless fit and finish.

Testing

Strength and reliability are non-negotiable. Every part undergoes rigorous stress-strain testing on our custom-built test stands to validate performance before it reaches our customers to ensure years of reliable operation.

Let customers speak for us

from 7 reviewsWith the pole length six feet, the overall strength of the carbon fiber and the titanium tip of 1/4 inch screw thread it has proven to be a valuable tool with my Insta360x5 video content for my off-road YouTube channel. Most selfie pools on the market are too thin. They break because they can not handle the ruff road conditions. And if they do not break they 'wabble' so much that the video is not acceptable to use in production.

Freaking love this hat. My favorite when I'm out and about!